Zinc Alloy Die Casting

Ukuphosa ukufa

Yintoni ukuphosa?

Ukuphoswa koxinzelelo kubizwa ngokuba yi-die casting

Indlela yokuphosa i-Die-casting apho ulwelo olutyhidiweyo lwe-alloy lugalelwa kwigumbi loxinzelelo,

i-cavity ye-mold yensimbi izaliswe ngesantya esiphezulu, kwaye i-alloy liquid iqiniswe phantsi koxinzelelo ukwenza i-casting.

I-advanteji kunye nokungalunganga kokuphosa ukufa:

I-advanteji: umgangatho olungileyo wemveliso ephezulu ixabiso elilungileyo

Ububi: imathiriyeli enomda kuphela i-aluminiyam ye-zinc ye-magnesium ekhokelela kwitoti yobhedu inokusetyenziselwa ukugalela ukuza kuthi ga ngoku.

Izixhobo ezixabisa kakhulu, kunye nezixhobo ezixabisa kakhulu

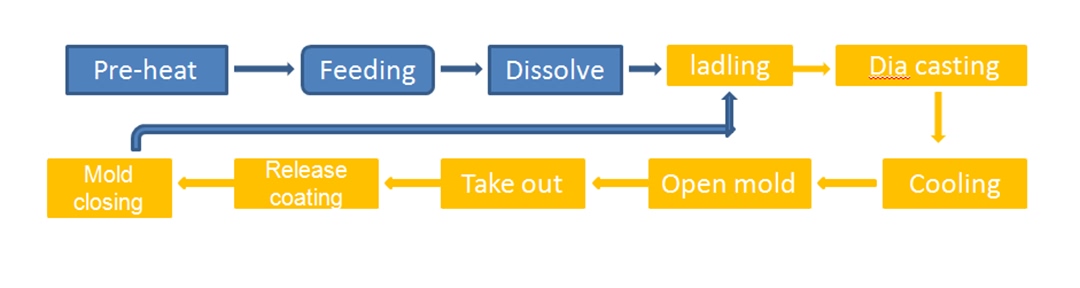

Ukufa-casting flow incoko:

Iinxalenye zokulahlwa komphezulu wokufa:

1.Ukupeyinta

2.Powder ukutyabeka

3.Ukucwenga

4.I-oxide anodizing

5.Ukupolisha, ukugquma

6.Ipeyinti yeoli

7.Ukuqhushumba kwamaso

Impazamo enkulu yokuphosa ukufa

Ngaphakathi: I-Stomata, umngxuma oshwabeneyo, umngxuma wesanti, ukhululekile

Umphezulu: Uqhekeko, ulwahlulo olubandayo, uhlobo olungalunganga, ibhillet enkulu, iqamza, idiphozithi yekhabhoni,

ukungunda okuncamathelayo, ubunzima, sag, trayisa, ipockmark, ukukhuhla, i-crack, igubu eliphezulu, ukugqobhoza

I-Die-casting yenye yeendlela eziphambili zokubumba isinyithi.Ngophuculo oluqhubekayo lwetekhnoloji ye-die-casting,

I-alloys yokuphosa i-die-casting ayisekho kuphela kwiintsimbi ezingenayo i-ferrous ezifana ne-zinc, i-aluminium, i-magnesium kunye nobhedu.Ubungakanani kunye nobunzima bokufa-

iindawo zokuphosa nazo ziya kwanda njengoko amandla omatshini wokufa anyuka, ngoko ke ithemba lokufa libanzi kakhulu.

Inkqubo yokuphosa iDie inoBungangamsha bayo nayo inemida yayo.Umgangatho, umgangatho kunye neendleko zeemveliso

zicutshungulwa ziinkqubo ezahlukeneyo zahlukile.Indlela yokukhetha ukulungiswa kwemveliso efanelekileyo

inkqubo kwinkqubo yemveliso ifuna ukuba sikhethe.

Ukuphosa ukufa

Yintoni ukuphosa?

Ukuphoswa koxinzelelo kubizwa ngokuba yi-die casting

Indlela yokuphosa i-Die-casting apho ulwelo olutyhidiweyo lwe-alloy lugalelwa kwigumbi loxinzelelo,

i-cavity ye-mold yensimbi izaliswe ngesantya esiphezulu, kwaye i-alloy liquid iqiniswe phantsi koxinzelelo ukwenza i-casting.

I-advanteji kunye nokungalunganga kokuphosa ukufa:

I-advanteji: umgangatho olungileyo wemveliso ephezulu ixabiso elilungileyo

Ububi: imathiriyeli enomda kuphela i-aluminiyam ye-zinc ye-magnesium ekhokelela kwitoti yobhedu inokusetyenziselwa ukugalela ukuza kuthi ga ngoku.

Izixhobo ezixabisa kakhulu, kunye nezixhobo ezixabisa kakhulu

Ukufa-casting flow incoko:

Iinxalenye zokulahlwa komphezulu wokufa:

1.Ukupeyinta

2.Powder ukutyabeka

3.Ukucwenga

4.I-oxide anodizing

5.Ukupolisha, ukugquma

6.Ipeyinti yeoli

7.Ukuqhushumba kwamaso

Impazamo enkulu yokuphosa ukufa

Ngaphakathi: I-Stomata, umngxuma oshwabeneyo, umngxuma wesanti, ukhululekile

Umphezulu: Uqhekeko, ulwahlulo olubandayo, uhlobo olungalunganga, ibhillet enkulu, iqamza, idiphozithi yekhabhoni,

ukungunda okuncamathelayo, ubunzima, sag, trayisa, ipockmark, ukukhuhla, i-crack, igubu eliphezulu, ukugqobhoza

I-Die-casting yenye yeendlela eziphambili zokubumba isinyithi.Ngophuculo oluqhubekayo lwetekhnoloji ye-die-casting,

I-alloys yokuphosa i-die-casting ayisekho kuphela kwiintsimbi ezingenayo i-ferrous ezifana ne-zinc, i-aluminium, i-magnesium kunye nobhedu.Ubungakanani kunye nobunzima bokufa-

iindawo zokuphosa nazo ziya kwanda njengoko amandla omatshini wokufa anyuka, ngoko ke ithemba lokufa libanzi kakhulu.

Inkqubo yokuphosa iDie inoBungangamsha bayo nayo inemida yayo.Umgangatho, umgangatho kunye neendleko zeemveliso

zicutshungulwa ziinkqubo ezahlukeneyo zahlukile.Indlela yokukhetha ukulungiswa kwemveliso efanelekileyo

inkqubo kwinkqubo yemveliso ifuna ukuba sikhethe.