Wholesale Price China Lost Wax Casting - Zinc Alloy Die Casting – Walley

Wholesale Price China Lost Wax Casting - Zinc Alloy Die Casting – Walley Detail:

Die casting

What is die-casting?

Pressure casting is called die casting

Die-casting method in which a molten alloy liquid is poured into a pressure chamber,

a cavity of a steel mold is filled at a high speed, and the alloy liquid is solidified under pressure to form a casting.

Advantage and disadvantage of die casting:

Advantage :good quality high production efficiency good price

Disadvantage: material limited only aluminum zinc magnesium lead copper tin can be used to casting so far.

Expensive equipment, and high cost tooling

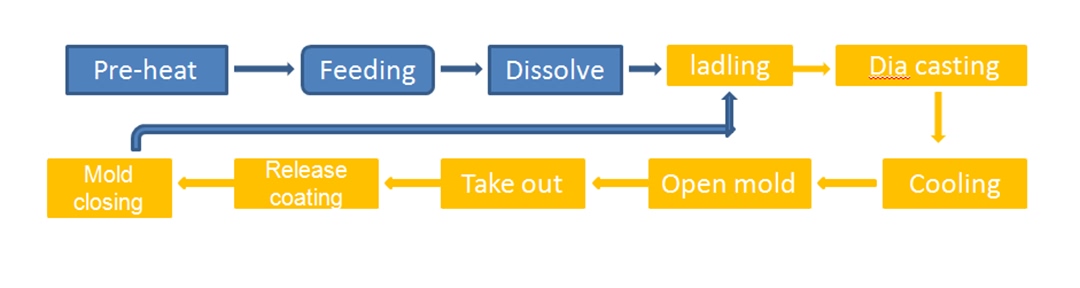

Die-casting flow chat:

Die casting parts surface treatment:

1.Painting

2.Powder coating

3.Plating

4.Oxide anodizing

5.Polishing, sanding

6.Oil painting

7.Bead blasting

The major flaw of die casting

Inside: Stomata, shrinkage hole, sand hole, loose

Surface: Crack, cold partition, wrong type, oversized billet, bubble, carbon deposit,

sticking mold, strain, sag, trace, pockmark, scouring, crack, top drum, piercing

Die-casting is one of the most advanced metal forming methods. With the continuous improvement of die-casting technology,

die-casting alloys are no longer limited to non-ferrous metals such as zinc, aluminum, magnesium and copper. The size and weight of die-

casting parts will also increase as the power of the die-casting machine increases, so the prospect of die-casting is very broad.

Die casting process has its Superiority also has its limitations. The quality, quality and cost of the products

processed by different processes are different. How to choose the right product processing

process in the production process requires us to choose.

Die casting

What is die-casting?

Pressure casting is called die casting

Die-casting method in which a molten alloy liquid is poured into a pressure chamber,

a cavity of a steel mold is filled at a high speed, and the alloy liquid is solidified under pressure to form a casting.

Advantage and disadvantage of die casting:

Advantage :good quality high production efficiency good price

Disadvantage: material limited only aluminum zinc magnesium lead copper tin can be used to casting so far.

Expensive equipment, and high cost tooling

Die-casting flow chat:

Die casting parts surface treatment:

1.Painting

2.Powder coating

3.Plating

4.Oxide anodizing

5.Polishing, sanding

6.Oil painting

7.Bead blasting

The major flaw of die casting

Inside: Stomata, shrinkage hole, sand hole, loose

Surface: Crack, cold partition, wrong type, oversized billet, bubble, carbon deposit,

sticking mold, strain, sag, trace, pockmark, scouring, crack, top drum, piercing

Die-casting is one of the most advanced metal forming methods. With the continuous improvement of die-casting technology,

die-casting alloys are no longer limited to non-ferrous metals such as zinc, aluminum, magnesium and copper. The size and weight of die-

casting parts will also increase as the power of the die-casting machine increases, so the prospect of die-casting is very broad.

Die casting process has its Superiority also has its limitations. The quality, quality and cost of the products

processed by different processes are different. How to choose the right product processing

process in the production process requires us to choose.

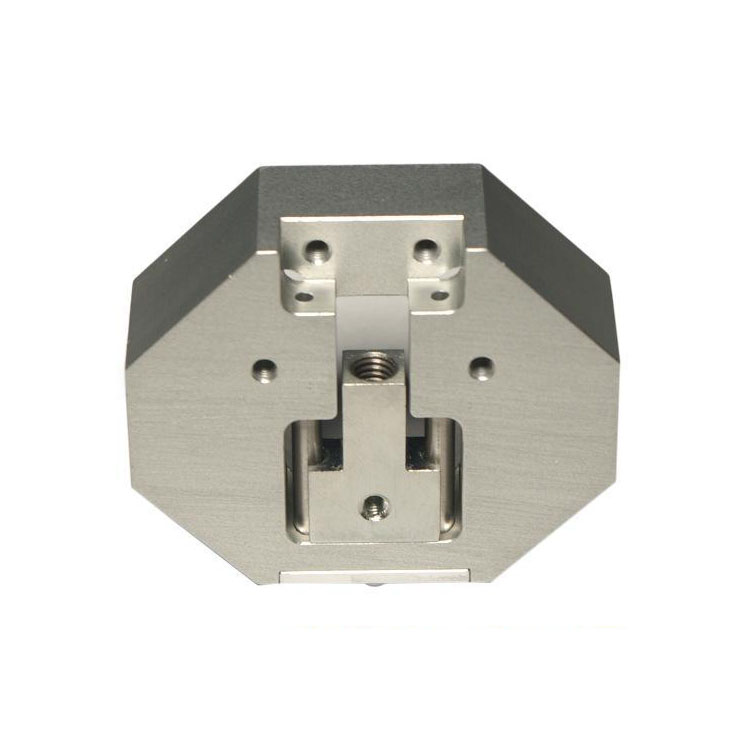

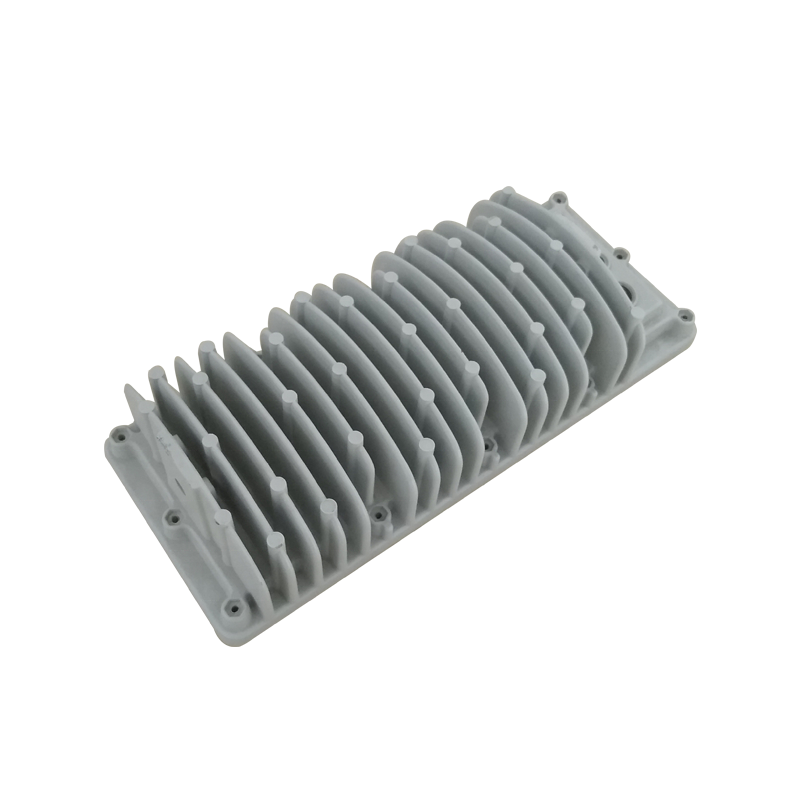

Product detail pictures:

Related Product Guide:

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for Wholesale Price China Lost Wax Casting - Zinc Alloy Die Casting – Walley , The product will supply to all over the world, such as: Philippines, kazan, New Orleans, We have the best products and professional sales and technical team.With the development of our company, we are able to provide customers best products, good technical support, perfect after-sales service.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!