Zinc Alloy Die Casting

Die casting

Chii chinonzi kufa-casting?

Pressure casting inonzi die casting

Die-casting nzira umo yakanyungudutswa alloy fluid inodururwa mukamuri yekumanikidza,

mhango yesimbi mold inozadzwa nekumhanya kukuru, uye alloy liquid inosimbiswa pasi pekumanikidzwa kuti igadzire kukanda.

Advantage uye kuipa kwekukanda kufa:

Advantage: yakanaka yemhando yepamusoro kugadzirwa kwakanaka mutengo wakanaka

Zvakaipa: zvinhu zvakaganhurirwa chete aluminium zinc magnesium inotungamira mhangura tin inogona kushandiswa kukanda kusvika zvino.

Zvishandiso zvinodhura, uye kudhura kwekushandisa

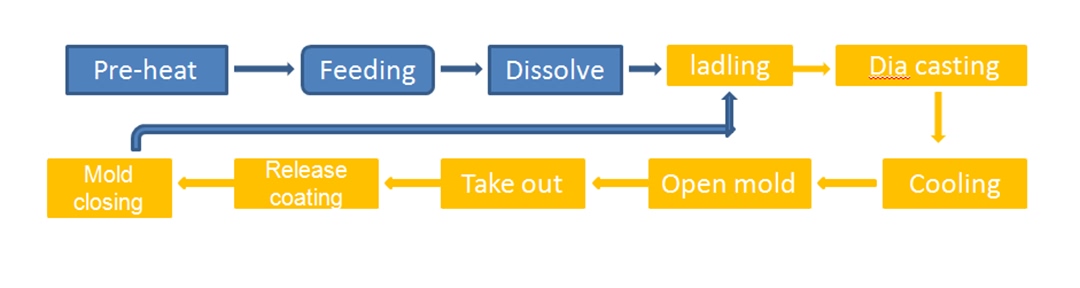

Die-casting flow chat:

Die casting parts surface treatment:

1.Painting

2.Powder coating

3.Plating

4.Oxide anodizing

5.Kupukuta, kujecha

6.Kupenda kwemafuta

7.Bead blasting

Chikanganiso chikuru chekukandira kufa

Mukati: Stomata, shrinkage gomba, gomba rejecha, rakasununguka

Pamusoro: Mutswe, kupatsanura kutonhora, mhando isiriyo, oversized billet, bubble, carbon deposit,

kunamatira mold, strain, sag, trace, pockmark, scouring, crack, top drum, kuboora

Die-casting ndeimwe yemhando yepamusoro yekugadzira simbi.Nekuenderera mberi kwekuvandudzwa kwe die-casting tekinoroji,

die-casting alloys haachagumiri kune asiri-ferrous simbi senge zinc, aluminium, magnesium nemhangura.Saizi uye uremu hwekufa-

zvikamu zvekukandira zvichawedzerawo sezvo simba remushini wekufa-kandira richiwedzera, saka tarisiro yekufa-kukanda yakakura kwazvo.

Die casting process ine Hukuru hwayo zvakare ine painogumira.Hunhu, kunaka uye mutengo wezvigadzirwa

zvinogadziriswa nemaitiro akasiyana zvakasiyana.Nzira yekusarudza yakakodzera chigadzirwa kugadzirisa

maitiro mukugadzira maitiro anoda kuti isu tisarudze.

Die casting

Chii chinonzi kufa-casting?

Pressure casting inonzi die casting

Die-casting nzira umo yakanyungudutswa alloy fluid inodururwa mukamuri yekumanikidza,

mhango yesimbi mold inozadzwa nekumhanya kukuru, uye alloy liquid inosimbiswa pasi pekumanikidzwa kuti igadzire kukanda.

Advantage uye kuipa kwekukanda kufa:

Advantage: yakanaka yemhando yepamusoro kugadzirwa kwakanaka mutengo wakanaka

Zvakaipa: zvinhu zvakaganhurirwa chete aluminium zinc magnesium inotungamira mhangura tin inogona kushandiswa kukanda kusvika zvino.

Zvishandiso zvinodhura, uye kudhura kwekushandisa

Die-casting flow chat:

Die casting parts surface treatment:

1.Painting

2.Powder coating

3.Plating

4.Oxide anodizing

5.Kupukuta, kujecha

6.Kupenda kwemafuta

7.Bead blasting

Chikanganiso chikuru chekukandira kufa

Mukati: Stomata, shrinkage gomba, gomba rejecha, rakasununguka

Pamusoro: Mutswe, kupatsanura kutonhora, mhando isiriyo, oversized billet, bubble, carbon deposit,

kunamatira mold, strain, sag, trace, pockmark, scouring, crack, top drum, kuboora

Die-casting ndeimwe yemhando yepamusoro yekugadzira simbi.Nekuenderera mberi kwekuvandudzwa kwe die-casting tekinoroji,

die-casting alloys haachagumiri kune asiri-ferrous simbi senge zinc, aluminium, magnesium nemhangura.Saizi uye uremu hwekufa-

zvikamu zvekukandira zvichawedzerawo sezvo simba remushini wekufa-kandira richiwedzera, saka tarisiro yekufa-kukanda yakakura kwazvo.

Die casting process ine Hukuru hwayo zvakare ine painogumira.Hunhu, kunaka uye mutengo wezvigadzirwa

zvinogadziriswa nemaitiro akasiyana zvakasiyana.Nzira yekusarudza yakakodzera chigadzirwa kugadzirisa

maitiro mukugadzira maitiro anoda kuti isu tisarudze.