OEM Manufacturer Cnc Machining Copper Part - EDM Machining Accessories – Walley

OEM Manufacturer Cnc Machining Copper Part - EDM Machining Accessories – Walley Detail:

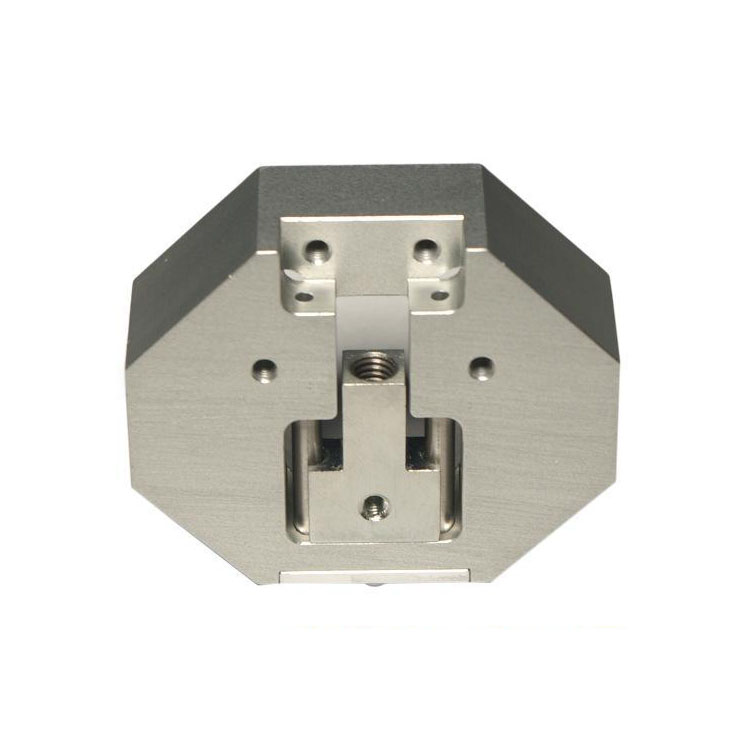

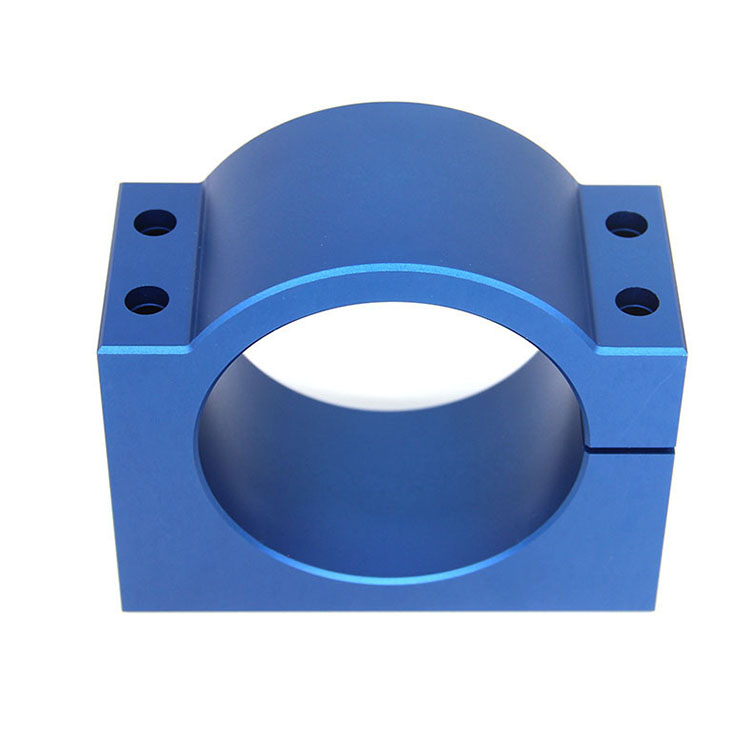

EDM Machining parts

The basis EDM process is very simple which is an electrical spark is created between the electrode spark with any electrically conductive material, it usually applies to some of the complex key points, plastic molds, undercut and small area, etc, our facilities ability for workpieces is up to 16 inches thick, and taper angles to 30+ degrees, We can handle parts up to 25.6” x 16” x 17.75″ workpieces.

Our fine wire cutting can produce true shapes and corners down to .001” with a minimum wire diameter of .003”. We are able to maintain tolerances as tight as ±.0008”. Our capabilities also include small-hole EDM drilling from .013 – .120” diameter in hard or soft materials.

Product Types

| Material | Copper,carbon steel, alloy steel, copper, stainless steel,etc. |

| Size | Customized according to your drawing. |

| Services | OEM, design, customized |

| Tolerance | +/-0.01mm to +/-0.002mm |

| Surface treatment | Passivation |

| *Polishing | |

| *Anodizing | |

| *Sand blasting | |

| *Electroplating(color, blue, white, black zinc, Ni, Cr, tin, copper, silver) | |

| *Black oxide coating | |

| *Heat-disposing | |

| *Hot-dip galvanizing | |

| *Rust preventive oil | |

| Certificate | ISO9001,IATF16949,ROHS |

| MOQ | Low MOQ |

| Delivery time | Within 15-20 workdays after deposit or payment received |

| Application | Auto Parts 、Electrical Appliances、Communication Devices、Medical Devices |

| Quality control | ISO standard,100% Whole range inspection through the production |

| After-sales Service | We will follow up every customer and solve all your problems satisfied after sales |

| Shipping Port | Shenzhen |

| Payment | TT;30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment. |

Advantage

1. Offering video and photos with details freely during production.

2. Producing according to the accuracy of drawings, assembly measurement to detect function and strict quality control to ensure 0 return rate

3. 99% orders can be ensured delivery time

4. The materials we use are optimal

5. 24 hours online service

6. The competitive factory price with the same quality and service

7. The most suitable packing method to different products.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" plus the theory of "quality the basic, have faith in the main and management the advanced" for OEM Manufacturer Cnc Machining Copper Part - EDM Machining Accessories – Walley , The product will supply to all over the world, such as: Sweden, Plymouth, Slovak Republic, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!