Low MOQ for Cnc Turning Dowel Pin - Aluminum CNC Milling Parts – Walley

Low MOQ for Cnc Turning Dowel Pin - Aluminum CNC Milling Parts – Walley Detail:

Why choose us:

1.We are a factory with more than 20 years cnc machining experience.

2.Approx 95% of our product are directly exported to USA/Canada/Australia/UK/France/Germany/Bulgaria/Poland/Italia/Netherlands…Quality assuranced.

3.Most of our machines are purchased from USA and Japan such as with brand HAAS(3-axis,4-asxis cnc milling machines), Brother, TSUGAMI(6-axis turning machine), Miyano and so on. so we are able to make high precision parts according to your tolerance requirements.

4.We can well control the surface finish such as polishing/ brush/ sand blasting, Normal anodize/harden anodize,black oxide, plating(Chrome/Nickel/zinc/gold/silver…)

5.Based on our good quality, good service and good credit record we have been selected as KA suppliers by Alibaba. Below link is some of our transaction history on Alibaba, you can have a look.

Voerly machinery is a fast growing manufacturer, and hope to become your partner in the future.

Our Machining Advantage

CNC milling allows us to quickly and accurately machine your parts from the stock material of your choice, in either plastic or metal. 2D and 3D shapes are easily created to a high standard of accuracy and surface finish. All CNC milling machine operations are programmed offline using Delcam Powermill software. Tool and job presetting help to ensure fast turnaround and accuracy. We used TaiQun and HURCO machines from Taiwan as well as some local Chinese brands for projects of less demanding complexity.

Our machining ability

| Precision of piece | +/-0.01mm,+/-0.005mm |

| Drawing format | JPEG,PDF,AI,DWG,DXF,IGS,STEP |

| Available materials | Metal: carbon steel, alloy steel, stainless steel,Aluminum,Brass etc. |

| Plastics: ABS,PMMA,PTFE,PE,POM,PA,UHMW, etc. | |

| Surface treatment | Metal:grinding, Polishing,Painting,bicolor-printing , Electroplating,Screen printing, Wiredrawing,Laser carving,anodizing etc. |

| Plastics: grinding, Polishing,Painting, bicolor-printing Electroplating,Screen printing,Laser carving etc. | |

| Features | Production Volume Prototype to Production |

| Precision CNC Machining Turning,Boring,Drilling,Countersinking, Thread Milling, Threading internal/external, Machining etc. |

We always pursue to provide customers with the best quality products based on reasonable prices. We implement product quality control through a combination of “prevention” and “inspection”, and provide safe and reliable quality control technology for production. CNC precision machining escorted to complete your entrustment.

Quality Assurance

Education and training is the best way to ensure the output of talents. Voerly regularly conducts quality seminars and quality learning meetings to improve the professional skills of quality personnel, master the latest technology, and meet the skills requirements of different positions.

Application :

Medical, Photoelectric,Auto market, communication,Aerospace and Defense,Aerospace,Security,Machinery.

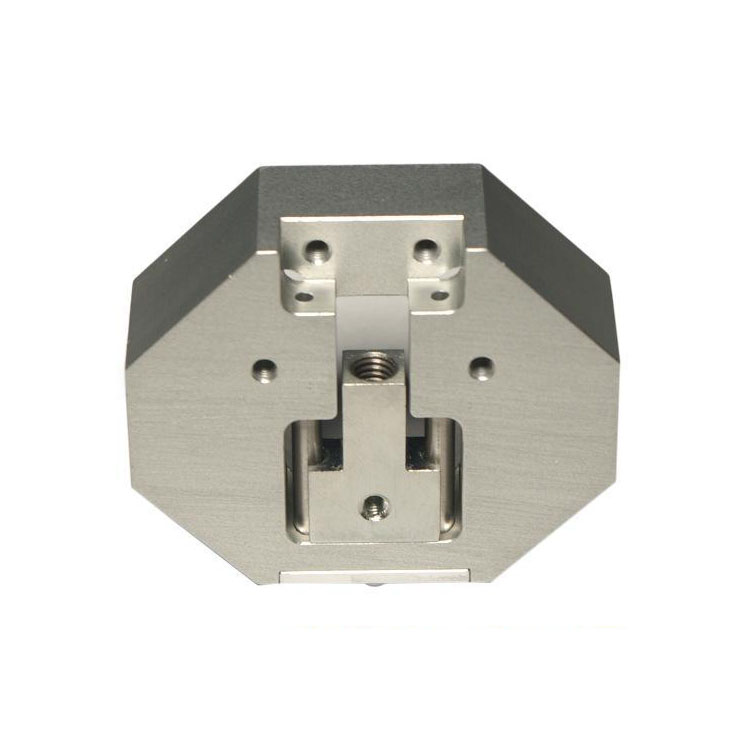

Product detail pictures:

Related Product Guide:

"Quality initial, Honesty as base, Sincere support and mutual profit" is our idea, so as to build repeatedly and pursue the excellence for Low MOQ for Cnc Turning Dowel Pin - Aluminum CNC Milling Parts – Walley , The product will supply to all over the world, such as: Czech, Niger, Egypt, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.