Zinc Alloy Tuag Casting

Tuag casting

Tuag-casting yog dab tsi?

Lub siab casting yog hu ua tuag casting

Txoj kev tuag-casting nyob rau hauv uas ib tug molten alloy kua yog poured rau hauv lub siab chamber,

cov kab noj hniav ntawm cov pwm hlau tau ntim rau ntawm qhov kub ceev, thiab cov kua hlau alloy yog solidified nyob rau hauv siab los tsim ib tug casting.

Qhov zoo thiab qhov tsis zoo ntawm kev tuag casting:

Advantage: zoo zoo siab ntau lawm efficiency zoo nqi

Disadvantage: cov khoom txwv tsuas yog aluminium zinc magnesium lead tooj liab tin tuaj yeem siv los ua kom deb li deb.

Cov khoom siv kim heev, thiab cov cuab yeej siv nyiaj siab

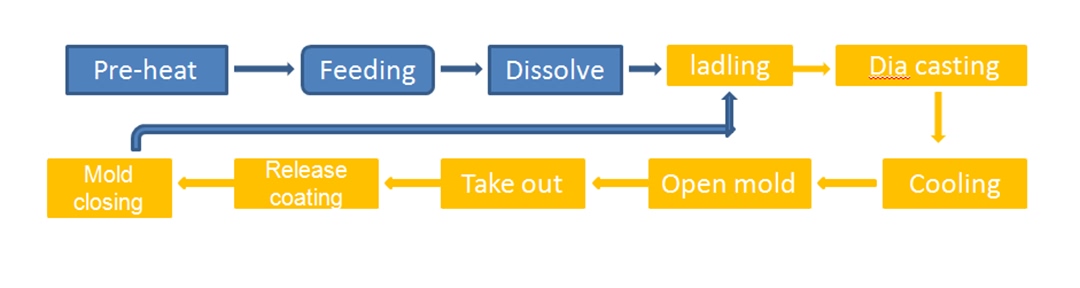

Tuag-casting flow chat:

Tuag casting qhov chaw deg kho:

1. Kev kos duab

2. hmoov txheej

3. Plating

4.Oxide anodizing

5.Polishing, xuab zeb

6.Oil painting

7.Bead blasting

Qhov teeb meem loj ntawm tuag casting

Sab hauv: Stomata, shrinkage qhov, xuab zeb qhov, xoob

Nto: tawg, txias muab faib, tsis ncaj ncees lawm hom, oversized billet, npuas, carbon deposit,

sticking pwm, lim, sag, kab, pockmark, scouring, tawg, sab saum toj nruas, tho

Tuag-casting yog ib qho ntawm cov txheej txheem ua hlau zoo tshaj plaws.Nrog kev txhim kho tas mus li ntawm kev tuag-casting tshuab,

Tuag-casting alloys tsis txwv rau cov hlau tsis-ferrous xws li zinc, aluminium, magnesium thiab tooj liab.Qhov loj thiab qhov hnyav ntawm tuag-

casting qhov chaw tseem yuav nce ntxiv raws li lub zog ntawm lub tshuab tuag-casting nce, yog li lub zeem muag ntawm kev tuag-casting yog dav heev.

Tuag casting txheej txheem muaj nws Superiority kuj muaj nws cov kev txwv.Qhov zoo, zoo thiab tus nqi ntawm cov khoom

ua tiav los ntawm cov txheej txheem sib txawv.Yuav ua li cas xaiv cov khoom tsim nyog

txheej txheem hauv cov txheej txheem ntau lawm xav kom peb xaiv.

Tuag casting

Tuag-casting yog dab tsi?

Lub siab casting yog hu ua tuag casting

Txoj kev tuag-casting nyob rau hauv uas ib tug molten alloy kua yog poured rau hauv lub siab chamber,

cov kab noj hniav ntawm cov pwm hlau tau ntim rau ntawm qhov kub ceev, thiab cov kua hlau alloy yog solidified nyob rau hauv siab los tsim ib tug casting.

Qhov zoo thiab qhov tsis zoo ntawm kev tuag casting:

Advantage: zoo zoo siab ntau lawm efficiency zoo nqi

Disadvantage: cov khoom txwv tsuas yog aluminium zinc magnesium lead tooj liab tin tuaj yeem siv los ua kom deb li deb.

Cov khoom siv kim heev, thiab cov cuab yeej siv nyiaj siab

Tuag-casting flow chat:

Tuag casting qhov chaw deg kho:

1. Kev kos duab

2. hmoov txheej

3. Plating

4.Oxide anodizing

5.Polishing, xuab zeb

6.Oil painting

7.Bead blasting

Qhov teeb meem loj ntawm tuag casting

Sab hauv: Stomata, shrinkage qhov, xuab zeb qhov, xoob

Nto: tawg, txias muab faib, tsis ncaj ncees lawm hom, oversized billet, npuas, carbon deposit,

sticking pwm, lim, sag, kab, pockmark, scouring, tawg, sab saum toj nruas, tho

Tuag-casting yog ib qho ntawm cov txheej txheem ua hlau zoo tshaj plaws.Nrog kev txhim kho tas mus li ntawm kev tuag-casting tshuab,

Tuag-casting alloys tsis txwv rau cov hlau tsis-ferrous xws li zinc, aluminium, magnesium thiab tooj liab.Qhov loj thiab qhov hnyav ntawm tuag-

casting qhov chaw tseem yuav nce ntxiv raws li lub zog ntawm lub tshuab tuag-casting nce, yog li lub zeem muag ntawm kev tuag-casting yog dav heev.

Tuag casting txheej txheem muaj nws Superiority kuj muaj nws cov kev txwv.Qhov zoo, zoo thiab tus nqi ntawm cov khoom

ua tiav los ntawm cov txheej txheem sib txawv.Yuav ua li cas xaiv cov khoom tsim nyog

txheej txheem hauv cov txheej txheem ntau lawm xav kom peb xaiv.