-

Chinese Professional Standoff Barrels - Injection Molds Parts – Walley

As a leading plastic injection mold China maker, we specializes in making various plastic injection moulds for automotive, home appliances, medical equipment, electronics and sporting equipment, as well as general industrial OEM applications. Our company covers an area of more than 3,800 square meters workshop, surrounded with convenient transportation . At present, our group reaches to more than 150 excellent toolmakers in china and capital assets to more than 15 million RMB. Our capacity is... -

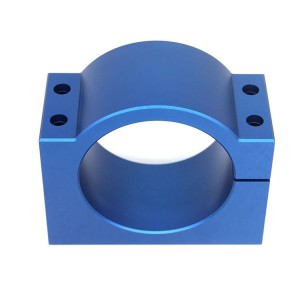

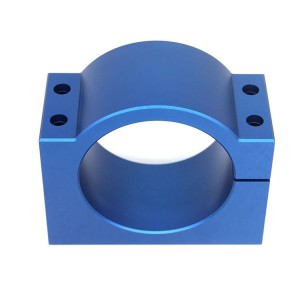

Hot-selling Cnc Machine Part - Aluminum CNC Milling Parts – Walley

Why choose us: 1.We are a factory with more than 20 years cnc machining experience. 2.Approx 95% of our product are directly exported to USA/Canada/Australia/UK/France/Germany/Bulgaria/Poland/Italia/Netherlands…Quality assuranced. 3.Most of our machines are purchased from USA and Japan such as with brand HAAS(3-axis,4-asxis cnc milling machines), Brother, TSUGAMI(6-axis turning machine), Miyano and so on. so we are able to make high precision parts according to your tolerance requirements. 4.... -

High definition Parts Of A Suction Machine - Stamping Aluminum – Walley

Stamping Parts Advantages Since press processing is often performed at room temperature, it is also called cold stamping. Stamping forming is one of the metal pressure processing methods. It is a material forming engineering technology based on the metal plastic deformation theory. The raw materials for stamping processing are generally sheet or strip, so it is also called sheet metal stamping. (1) The dimensional accuracy of the stamping parts is guaranteed by the mold, and has the same... -

China Cheap price Precision Cnc Machining - EDM Machining Accessories – Walley

EDM Machining parts The basis EDM process is very simple which is an electrical spark is created between the electrode spark with any electrically conductive material, it usually applies to some of the complex key points, plastic molds, undercut and small area, etc, our facilities ability for workpieces is up to 16 inches thick, and taper angles to 30+ degrees, We can handle parts up to 25.6” x 16” x 17.75″ workpieces. Our fine wire cutting can produce true shapes and corners down to .001” wi... -

Chinese wholesale Turning Auto Parts Inserts - Stamping Aluminum – Walley

Stamping Parts Advantages Since press processing is often performed at room temperature, it is also called cold stamping. Stamping forming is one of the metal pressure processing methods. It is a material forming engineering technology based on the metal plastic deformation theory. The raw materials for stamping processing are generally sheet or strip, so it is also called sheet metal stamping. (1) The dimensional accuracy of the stamping parts is guaranteed by the mold, and has the same... -

Quality Inspection for Packing Machine Spare Parts - Stamping Aluminum – Walley

Stamping Parts Advantages Since press processing is often performed at room temperature, it is also called cold stamping. Stamping forming is one of the metal pressure processing methods. It is a material forming engineering technology based on the metal plastic deformation theory. The raw materials for stamping processing are generally sheet or strip, so it is also called sheet metal stamping. (1) The dimensional accuracy of the stamping parts is guaranteed by the mold, and has the same... -

2020 Good Quality 5 Axis Cnc Machining - EDM Machining Accessories – Walley

EDM Machining parts The basis EDM process is very simple which is an electrical spark is created between the electrode spark with any electrically conductive material, it usually applies to some of the complex key points, plastic molds, undercut and small area, etc, our facilities ability for workpieces is up to 16 inches thick, and taper angles to 30+ degrees, We can handle parts up to 25.6” x 16” x 17.75″ workpieces. Our fine wire cutting can produce true shapes and corners down to .001” wi... -

Professional Design Heavy Equipment Parts For Heavy Industries - Stamping Aluminum – Walley

Stamping Parts Advantages Since press processing is often performed at room temperature, it is also called cold stamping. Stamping forming is one of the metal pressure processing methods. It is a material forming engineering technology based on the metal plastic deformation theory. The raw materials for stamping processing are generally sheet or strip, so it is also called sheet metal stamping. (1) The dimensional accuracy of the stamping parts is guaranteed by the mold, and has the same... -

Factory directly Domestic Sewing Machine Parts - Stamping Aluminum – Walley

Stamping Parts Advantages Since press processing is often performed at room temperature, it is also called cold stamping. Stamping forming is one of the metal pressure processing methods. It is a material forming engineering technology based on the metal plastic deformation theory. The raw materials for stamping processing are generally sheet or strip, so it is also called sheet metal stamping. (1) The dimensional accuracy of the stamping parts is guaranteed by the mold, and has the same... -

Factory supplied Aluminum Helicopter Component - Zinc Alloy Die Casting – Walley

Die casting What is die-casting? Pressure casting is called die casting Die-casting method in which a molten alloy liquid is poured into a pressure chamber, a cavity of a steel mold is filled at a high speed, and the alloy liquid is solidified under pressure to form a casting. Advantage and disadvantage of die casting: Advantage :good quality high production efficiency good price Disadvantage: material limited only aluminum zinc magnesium lead copper tin can be used to casting so far. Expe... -

Reliable Supplier Copper Fitting - Injection Molds Parts – Walley

As a leading plastic injection mold China maker, we specializes in making various plastic injection moulds for automotive, home appliances, medical equipment, electronics and sporting equipment, as well as general industrial OEM applications. Our company covers an area of more than 3,800 square meters workshop, surrounded with convenient transportation . At present, our group reaches to more than 150 excellent toolmakers in china and capital assets to more than 15 million RMB. Our capacity is... -

Hot New Products Medical/Surgical Part - Stamping Aluminum – Walley

Stamping Parts Advantages Since press processing is often performed at room temperature, it is also called cold stamping. Stamping forming is one of the metal pressure processing methods. It is a material forming engineering technology based on the metal plastic deformation theory. The raw materials for stamping processing are generally sheet or strip, so it is also called sheet metal stamping. (1) The dimensional accuracy of the stamping parts is guaranteed by the mold, and has the same...