Chinese wholesale Die Casting Enclosure Part - Zinc Alloy Die Casting – Walley

Chinese wholesale Die Casting Enclosure Part - Zinc Alloy Die Casting – Walley Detail:

Die casting

What is die-casting?

Pressure casting is called die casting

Die-casting method in which a molten alloy liquid is poured into a pressure chamber,

a cavity of a steel mold is filled at a high speed, and the alloy liquid is solidified under pressure to form a casting.

Advantage and disadvantage of die casting:

Advantage :good quality high production efficiency good price

Disadvantage: material limited only aluminum zinc magnesium lead copper tin can be used to casting so far.

Expensive equipment, and high cost tooling

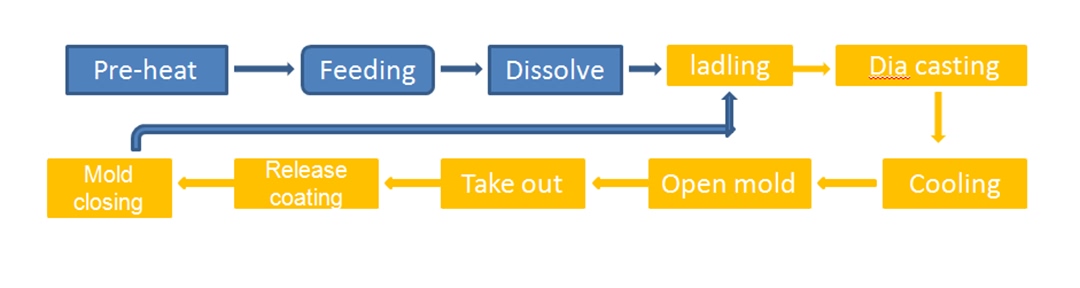

Die-casting flow chat:

Die casting parts surface treatment:

1.Painting

2.Powder coating

3.Plating

4.Oxide anodizing

5.Polishing, sanding

6.Oil painting

7.Bead blasting

The major flaw of die casting

Inside: Stomata, shrinkage hole, sand hole, loose

Surface: Crack, cold partition, wrong type, oversized billet, bubble, carbon deposit,

sticking mold, strain, sag, trace, pockmark, scouring, crack, top drum, piercing

Die-casting is one of the most advanced metal forming methods. With the continuous improvement of die-casting technology,

die-casting alloys are no longer limited to non-ferrous metals such as zinc, aluminum, magnesium and copper. The size and weight of die-

casting parts will also increase as the power of the die-casting machine increases, so the prospect of die-casting is very broad.

Die casting process has its Superiority also has its limitations. The quality, quality and cost of the products

processed by different processes are different. How to choose the right product processing

process in the production process requires us to choose.

Die casting

What is die-casting?

Pressure casting is called die casting

Die-casting method in which a molten alloy liquid is poured into a pressure chamber,

a cavity of a steel mold is filled at a high speed, and the alloy liquid is solidified under pressure to form a casting.

Advantage and disadvantage of die casting:

Advantage :good quality high production efficiency good price

Disadvantage: material limited only aluminum zinc magnesium lead copper tin can be used to casting so far.

Expensive equipment, and high cost tooling

Die-casting flow chat:

Die casting parts surface treatment:

1.Painting

2.Powder coating

3.Plating

4.Oxide anodizing

5.Polishing, sanding

6.Oil painting

7.Bead blasting

The major flaw of die casting

Inside: Stomata, shrinkage hole, sand hole, loose

Surface: Crack, cold partition, wrong type, oversized billet, bubble, carbon deposit,

sticking mold, strain, sag, trace, pockmark, scouring, crack, top drum, piercing

Die-casting is one of the most advanced metal forming methods. With the continuous improvement of die-casting technology,

die-casting alloys are no longer limited to non-ferrous metals such as zinc, aluminum, magnesium and copper. The size and weight of die-

casting parts will also increase as the power of the die-casting machine increases, so the prospect of die-casting is very broad.

Die casting process has its Superiority also has its limitations. The quality, quality and cost of the products

processed by different processes are different. How to choose the right product processing

process in the production process requires us to choose.

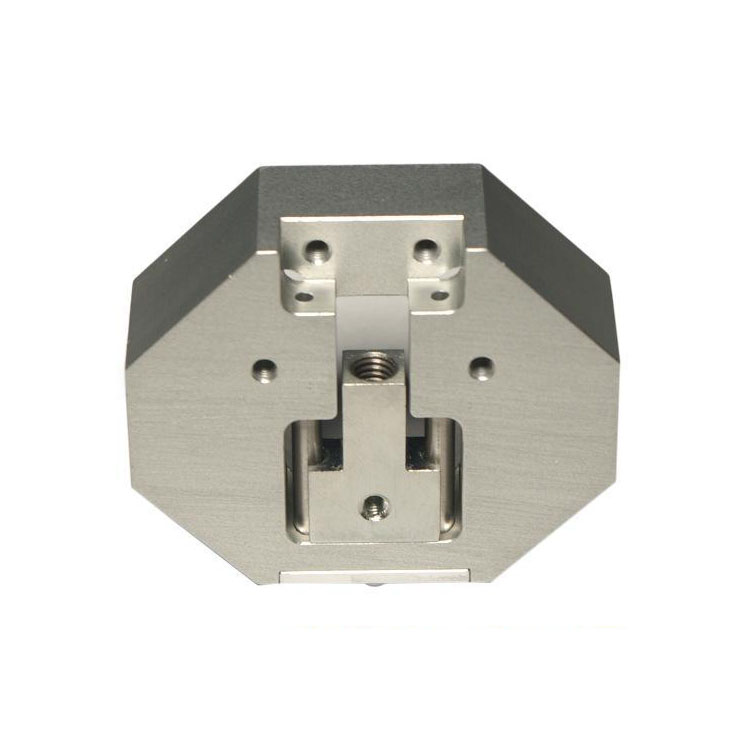

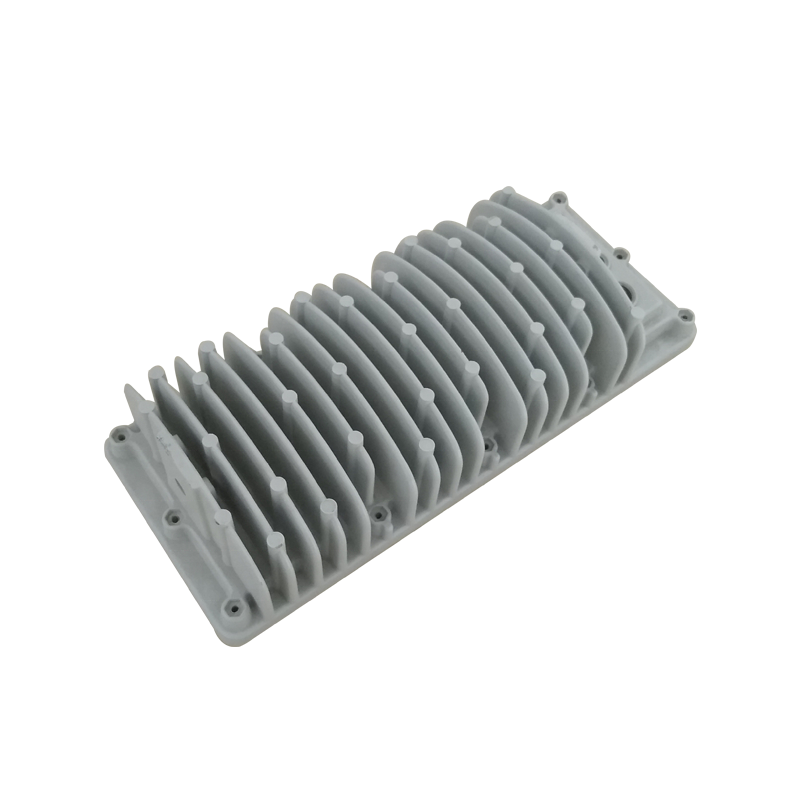

Product detail pictures:

Related Product Guide:

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for Chinese wholesale Die Casting Enclosure Part - Zinc Alloy Die Casting – Walley , The product will supply to all over the world, such as: Rio de Janeiro, Iran, luzern, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.